Technology Section Feature

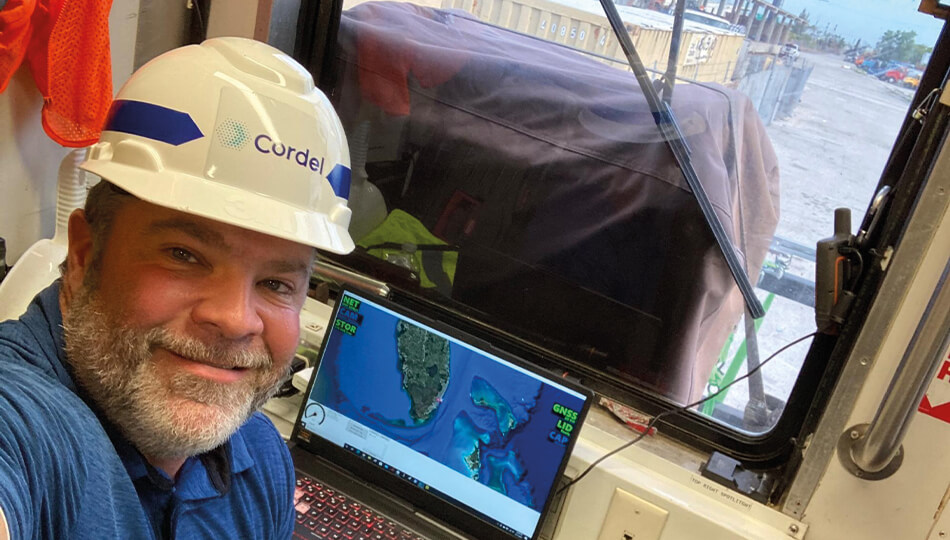

Erik Henderson

Global Head of Rail Solutions, Cordel

Ex Technical Director – Enterprise GIS & Field Services, CSX Technology

Vice Chair, ARDA Technology Section

If you’re looking to take advantage of LiDAR Data Collection, you have several options for deploying it along your Railroad’s Right-of-Way:

- Aerial (drone or helicopter)

- Employee Driven (Ex: Track Inspector) Hi-Rail

- Vendor Operated (Track Defect Testing) Hi-Rail

- Rail-Owned Geometry Car

- Autonomous Track Inspection Cars

LiDAR is LiDAR in essentially all of these applications. You’ll have an easier time getting around the yards and capturing images of roof conditions and light poles if you use aerial-based LiDAR. But you’ll get closer and more accurate imaging of ground-based assets if you mount on a ground-based vehicle. The decision depends on your timeframes and scanning needs.

What I’d like to talk about is ground-based collection along the line of the road. If you’ve determined you need or want to scan the line-of-road to start utilizing LiDAR for any of the long lists of valuable information it can provide, you need to decide how and where to mount it. Most roads are still in the R&D phase of implementing LiDAR which means they want to have skilled operators with hands-on experience. Under most circumstances of implementing new technology, I’d say this is necessary. When it comes to mobile rail scanning, with the right system in place, you can truly deploy a “set it and forget it” scanner. Now since I’m the one writing the blog, I get to toot the horn of Cordel since I’ve come to experience it and they really know how to get this done!

Deploying LiDAR on in-service vehicles can maximize revenue traffic.

Deploying LiDAR on in-service vehicles can maximize revenue traffic.

Ok, you want mobile rail-based, and I’ve clearly convinced you Cordel is the way to go, now let’s talk about the deployment. The name of the game in freight rail is to keep the trains moving and to minimize any kind of track time for maintenance, right? Most roads today deploy a fleet of track testing vehicles or geometry cars that are either manned with skilled technicians or more recently, autonomously testing in boxcars as they are pulled along in the consist of a revenue train. If you are looking to consistently record, update and monitor your network, these are the ideal platforms to implement your LiDAR equipment. They allow you to continuously map your network without any additional track maintenance time taking away from revenue trains.

The Geometry Car fleet already has a staff of technicians who are able to monitor the equipment in real-time and can assist in data offloading, should there be any communications issues. All roads still face the balance between wanting video and/or imagery along with their LiDAR, but not having a reliable, high-speed connection for consistent download. The easiest solution here is the manual hard drive swap, but that requires human interaction. Another option is to set up an on-demand download for when you are in good coverage and can be offloaded while still underway. This is something that could be set up and done for the autonomous rail car setup.

A Cordel LiDAR scanner, after 40,000 miles of operation.

A Cordel LiDAR scanner, after 40,000 miles of operation.

I know you’re probably thinking: why offload all the data when we should be “edge computing”? Well, that’s true to some point, if your goal and need are to find and identify issues in real-time but unfortunately LiDAR works a little differently. LiDAR creates a digital twin of your network that allows you to virtually visit, explore, linearly measure, volume measure, compare clearances, check for ballast deficiencies, compare environments run-over-run, visualize lines-of-sight, and many more functions. All of these require complex and customized algorithms to be run against clean data. Now, this doesn’t mean they are not available; they are. They are just being done within the first few days after a run is completed and the data offloaded.

With that said, we want to hear about your problems. What are the asks, what data is needed, what comparison made, what change details found? When the questions can be observed and solved first with LiDAR using some manual intervention, then the automated processing work can begin so that that coveted edge computing can be realized.

Let me know what your railroad’s challenges are. Drop me a note at: cordel.ai/contact

About the Author

Transform your infrastructure inspections

Visit our contact page to get started today or book a demo to give us the opportunity to show you first hand how we enable deeper insights into critical infrastructure.