Technology Section Feature

Erik Henderson

Global Head of Rail Solutions, Cordel

Ex Technical Director – Enterprise GIS & Field Services, CSX Technology

Vice Chair, ARDA Technology Section

“Don’t do anything that interrupts the flow of train traffic!” That’s the guidance I was given several years ago at CSX when we were sorting out the complexities of Positive Train Control (PTC) regulations. We had to figure out how we were going to survey the entire railroad to a level of accuracy never before acquired. When we were done, we then had to process that into a newly created industry data model and field-validate that every asset we just collected was represented correctly. Then we’re done? Nope, every change ever made on the railroad from that day forward had to be sent right through the same process, but this time it has to be done and loaded on the next train that rolls by! Oh, and remember that opening line: don’t do anything that interrupts the flow of train traffic. It was time to think outside the box.

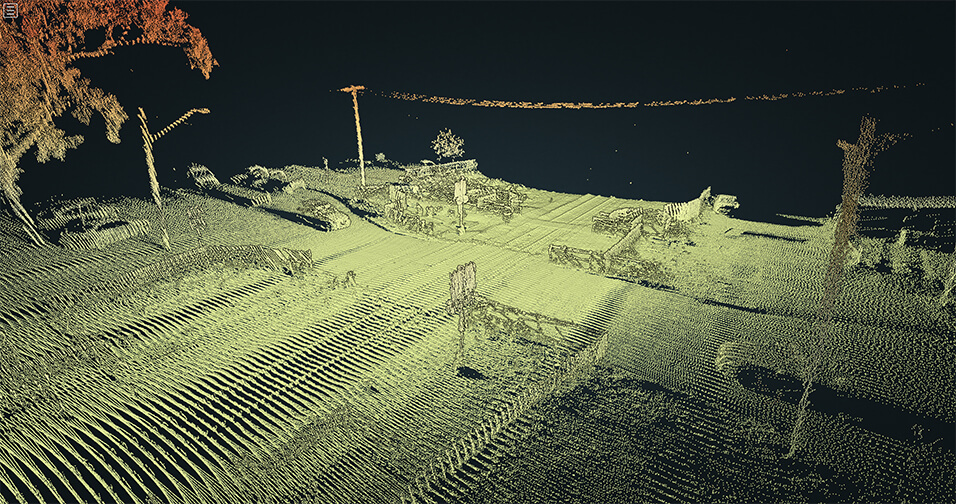

This article will try to explain the benefits of utilizing what I’m calling advanced survey methods for field data collection on the railroad. What is advanced survey methods? I’ve been in the Surveying and GIS industry for over 20 years now and have seen quite a transition from traditional surveying with a rodman and instrument man carrying around transit and prism. Today, we utilize Unmanned Aerial Vehicles (UAV) or drones, Light Detection and Ranging (LiDAR) and 360° cameras for a variety of business use cases. I will try to walk through some use cases that demonstrate what value can be realized with an investment in these technologies.

Legal

At CSX, when we got asked to provide support for legal cases, often it was in some form of scene recreation or documentation of existing conditions. One of the more valuable benefits to this form of data collection is the complete picture it paints. Traditional survey requires time to be spent at every single asset. LiDAR collection simply requires the laser to pass within sight, and a certain distance depending on your hardware, of anything you want to collect.

In one scenario, a motor vehicle became stuck on a road crossing and was eventually struck by a passing train. Litigation followed that questioned whether the railroad had sufficiently maintained the elevation of the tracks or if they had been raised over time, causing the unsafe condition. What was needed was an accurate depiction of existing conditions so it could be compared against historical conditions. Our team was dispatched to drive the section of track with a hi-rail-mounted LiDAR unit. We were then able to obtain commercially available historical LiDAR data, collected by various state agencies, over several periods of time. We matched up the two datasets using common points like building rooflines and utilities. The data comparison was able to prove that not only were the tracks kept at a near identical elevation, the crossing streets approach had dropped a number of inches.

Sometimes railroad technical groups approach a request with one solution in mind and have to shift on the fly to pull out another tool from the toolbox. We were called in when visual confirmation of conditions wasn’t possible from accessible road crossings. We had a portion of abandoned track where a local resident had placed a fence along our right-of-way, potentially up to a mile long, and was asked to remove it. Our plan was to drive in as far as we could and fly a drone in to document the removal. Upon arrival, the heavy tree cover negated the use of aerial imagery so we mounted our 360° Garmin camera and began recording while travelling down the corridor. These cameras store a lat/long coordinate with every shot which allowed us to very clearly depict exactly where each photo was taken, and in a live map, for our legal team to review. There was never any question or concern of where the photos were taken or at what angle we faced. All that info is stored in the photo and presented in a Google Street View-like map. Have you ever sat around a monitor looking through a folder of images labelled something like IMG2406.jpg and wondered where it was taken, when and at what angle? Not anymore.

Environmental

Another advantage to LiDAR is the small portable size of the lasers. At CSX, we scanned the railroad with LiDAR mounted on the hood of our hi-rails, connected to a backpack as a walking unit and flown from both a helicopter and drone. This allows you to get over buildings, under bridges and inside tunnels and buildings. Along with the collection methods, there are various ways to process the data and classify your point clouds. When you collect in an area with a lot of tree cover, it is beneficial to classify the vegetation so that it can be removed to look directly at the ground.

Spills are an unfortunate reality sometimes and being able to capture and stop run-off is critical. In one such incident in a large yard, we were asked if we could help locate a possible stormwater outfall that had not been seen in some time. Luckily, we had captured the area via helicopter and processed the points to classify the vegetation. Traditional survey is often used to build digital terrain models so you can imagine the level of clarity and accuracy when you build one from a LiDAR point cloud. Once built, were able to easily recognize the swale pattern under the heavy vegetation that ran off towards a nearby stream.

I’ll go back to my previous comment about using multiple tools in the toolbox. In 2018, CSX’s Field Services team responded to Hurricane Florence to provide real-time damage assessments for the headquarters management team. We were utilizing a mobile collection app to quickly record damage assessments and provide real-time imagery along with each assessment. Camera phones, 360° photography and drone imagery was all being uploaded via cell connection and displayed on a central hurricane response map in the “war room”. The HQ staff was reviewing imagery of a derailment and did not have clear visibility of the car numbers of some of the overturned cars. A quick call to the drone pilot on site resulted in more imagery directly overhead that captured those numbers, allowing our team to identify the contents and pass it on to emergency responders, along with that imagery.

Economic Development

Despite the fact that these tools can be used for highly precise measurements and recording, sometimes they can be used simply for their crystal clear quality, like marketing flyover videos. Over the years my teams have been asked by Corporate Communications, Real Estate and Sales & Marketing each for different types of flyover videos. You can find these departments at each of the railroads and all have probably contracted at one point with consulting companies who can fly drones for this purpose. Again, what I am trying to demonstrate is the value in investing in this technology and leveraging this capability.

We were able to capture the redevelopment of a large yard throughout the various stages without incurring repeated expenses from a third party consultant. Safety is always every railroad’s number one concern and it’s advantageous to utilize railroad employees to enter property and capture video footage, removing the need for outside contractors to come into an area they are potentially unfamiliar with. We simply become the data gatherers and pass that video on to the experts for processing. This is true for site assessments for marketing, as-builting for design & construction and all sorts of other promotional videography.

Real Estate

Cost recovery and return on investment are always popular buzzwords when I have meetings about railroads’ investment in these technologies. In most cases, railroads are collecting data for the use of PTC but are also always looking for other teams who can make use of that collection. Whichever department handles your utility crossing contracts, they are most likely discovering undocumented or non-contracted crossings passively. They may not have the personnel to go out and ride the rails looking out for these offenders. 360° photography or video, drone imagery and LiDAR can all be used for this ancillary benefit. Railroad technical teams are often working to feed each of these to their Real Estate team so they don’t have to venture out looking but instead can utilize a variety of desktop analysis tools at their disposal to identify and locate these from the office. LiDAR equipment has become much more of a mainstream tool for collection which has led to a host of new analytics tools for processing. CSX has been utilizing and realizing the benefits of LiDAR for over 12 years now and have worked with it on several software platforms. Each have created filters which allows a user to load a point cloud and apply a filter looking for certain distinct patterns in the cloud. Rail filters are used to locate and draw each one of the rails found in the point cloud. Very similar to track is overhead wires. These filters can auto- detect and generate line work that matches the shape and characteristics of the wires. These filters further reduce the manual time of a technician walking the track on screen looking for wires. Now, they can skip one by one through the identified assets and compare against a list of known utility crossings.

A lot has been said over the years about the financial costs of PTC versus the benefits. I’ve decided to leave those arguments to folks who have a lot more time on their hands. Since we first utilized LiDAR over twelve years ago, prices have dropped significantly to the point where railroads can purchase, learn and use the equipment ourselves, either directly or As-A-Service provided by specialist vendors. Some providers now take this one step further, using AI to analyze the raw data and provide actionable reports directly to the railroad’s own teams for clearances, vegetation, ballast, etc.. I am confident these advances have already proven a return on our investment for railroads and adopters will continue to benefit for a long time. With these technologies, railroads’ GIS Departments are working to reap every last benefit they can out of the investment made for PTC to make railroads safer, more efficient and to increase shareholder value.

About the Author

Transform your infrastructure inspections

Visit our contact page to get started today or book a demo to give us the opportunity to show you first hand how we enable deeper insights into critical infrastructure.